---

If you're already purchasing an RV holding tank from us, chances are you will need the fittings installed specific to your application. The kit contains the fittings you need to customize your tank to your needs.

ElkhartRVParts.com Black and Grey Water Tanks Fitting Kit Installation PDF Click Here

Here is what is included in the kit:

- 4 x #311 - Probe screen covers for enhanced sensor protection and accurate readings

- 4 x #A2A2 - Horst Miracle Probe mini probe/sensor tank inserts with hooded debris protection

- 3 x #BI-B11150B - 1-1/2" ABS barbed coupler

- 1 x #BI-B1130B - 3" ABS barbed coupler

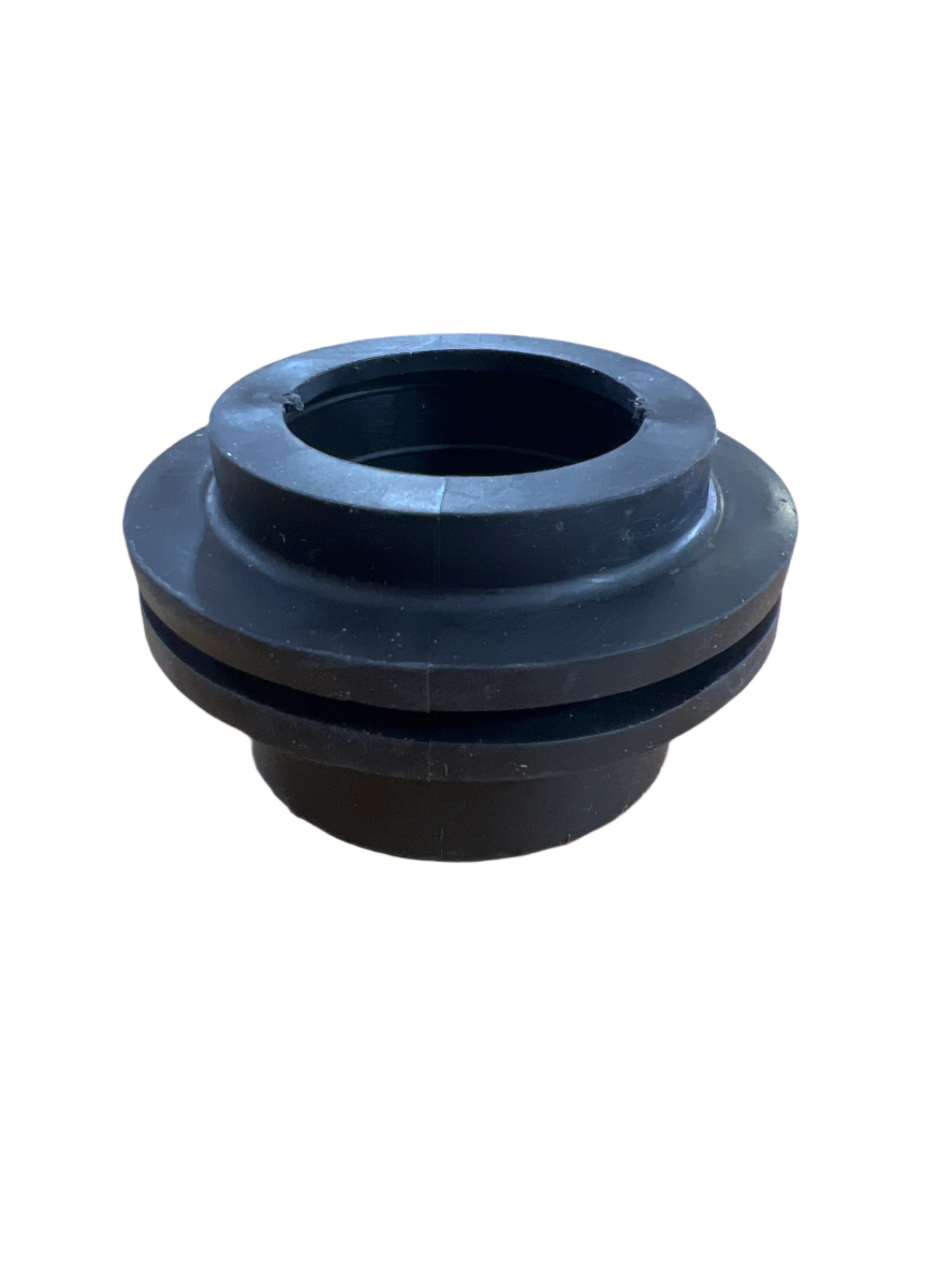

- 3 x #BI-B1115 - 1-1/2" grommets

- 1 x #BI-B113 - 3" grommet

Here is what you will need (not included in the kit):

- 3/8" drill bit (needed for installing sensors)

- 2-1/2" hole saw (needed for 1-1/2" grommets)

- 4" hole saw (needed for 3" grommet)

- drill (electric or cordless)

- safety goggles

- tape measure

- dish or hand soap

- deburring tool (knife or rough sand paper will work too)

******************************************************************************************

Steps to install grommets and barbed couplers: Note that your pipe size will determine which size grommets and couplers you will need to install.

1) Mark the tank exactly where you want to place fittings (double check your measurements to prevent an error)

2) Make a starter hole for your hole saw

3) Then cut your tank hole with the hole saw

4) Deburr the hole (important to create a tight seal)

5) Push short end of grommet with your hand into the hole till flush (check all sides to make sure seated smoothly

6) Take the barbed coupler, apply a little dish soap around barbed side & push barbed coupler with your hand into grommet until you hear it snap and lock into position. Do not push any further to prevent damage or possibility of leaks.

Steps to install sensors in standard formation. Sensors are used to measure water level. (please check w/tank manufacturer if unsure of where sensors should be placed) Note: Keep sensors at least a fingers-width from edges so probes/sensors seal properly). Sensors are easy to install and are helpful to keep track of your tank levels.

1) Mark the tank exactly where you want to place your probes at end of tank (double check your measurements to prevent an error).

a) Probes/sensors are typically placed at the end of the tank at top center (to measure when tank is full)

b) Next probe is placed at the middle end of tank between the middle and side of the tank (to measure when the tank is half-way full)

c) The next probe is placed at the bottom towards the right corner (to measure when the tank is empty)

d) The last probe is placed at the bottom towards the center (to measure again when the tank is empty)

2) Now drill the 4 holes for the probes using your 3/8" drill bit. Remove any burrs to get a tight seal

3) Push probe sensor into the hole, wiggling into place then twist nut to tighten

*******************************************************************************************

If you don't want this DIY project, we can install the fittings for you!

See our custom installation options here>

Why use our custom tank welding process for your fittings?

• OEM Certified Application Process.

• Get your tank the same way it was installed the day you bought it.

• Permanent Leak Proof Process.

• Tank welding ensures no seam or void can develop at your fitting which is a traditional stress point.

• Simple For You.

• The tools and training to custom spin weld fittings onto a holding tank are expensive.

• Let our staff do it for you to get it right the first time.

• Triple QC Check: Every tank we add spin welded fittings to undergoes a rigorous Triple Quality Control Test.

• Impact Proof: Your fittings will be tested for durability to ensure a permanent seal has been made.

• Air Tight: Air is thinner than water, so we pressure test your tank by injecting air and spraying a special soap like solution on the seams to look for seal voids.

• Water Tight: Once complete, we submerge your tank underwater and check for bubbles and leaks.

| Width (inches) | 8 |

|---|---|

| Height (inches) | 6 |

| Length (inches) | 10 |

| Weight (pounds) | 4.2 |

| Probe inserts model | A2A2 |

| 3 inch grommet model | BI-B113 |

| Probe inserts material | Horst Miracle Probe mini probe/sensor tank inserts with hooded debris protection |

| Probe inserts quantity | 4 |

| 3 inch grommet quantity | 1 |

| 1-1/2 inch grommets model | BI-B1115 |

| Probe screen covers model | 311 |

| 1-1/2 inch grommets quantity | 3 |

| Probe screen covers quantity | 4 |

| 3 inch abs barbed coupler model | BI-B1130B |

| 3 inch abs barbed coupler quantity | 1 |

| 1-1/2 inch abs barbed couplers model | BI-B11150B |

| 1-1/2 inch abs barbed couplers quantity | 3 |

- What components are included in the universal holding tank fittings kit? The kit includes 4 probe screen covers (#311), 4 Horst Miracle Probe mini probe/sensor tank inserts (#A2A2), 3 1-1/2" ABS barbed couplers (#BI-B11150B), 1 3" ABS barbed coupler (#BI-B1130B), 3 1-1/2" grommets (#BI-B1115), and 1 3" grommet (#BI-B113).

- What tools do i need to install the fittings and sensors from this kit? You will need a 3/8" drill bit, 2-1/2" hole saw, 4" hole saw, drill (electric or cordless), safety goggles, tape measure, dish or hand soap, and a deburring tool such as a knife or rough sandpaper.

- Can this kit be used for both black water and grey water rv tanks? Yes, this Universal Holding Tank Fittings Kit is designed for use with both black water and grey water RV tanks.

- Is there an option to have the fittings professionally installed? Yes, if you prefer not to do the installation yourself, Elkhart RV Parts offers a custom fittings installation service where they professionally spin weld the fittings onto your tank.

- How do i install the sensors to measure the tank water levels? You should mark the tank where you want the probes, typically placing them at the top center, middle end between the middle and side, bottom right corner, and bottom center. Drill 3/8" holes at these locations, deburr the holes, insert the probes by wiggling them into place, and then twist the nuts to tighten.

Factory-Fresh OEM Parts — the same brands installed in new RVs straight from Elkhart. Genuine, name-brand components made to order — never generic, never outdated. Sourced directly from the original RV manufacturers for perfect fit and factory-level quality.